Parameters Description

Temperature control range:-45°C ~ 250°C ;Power range:2.5kW~25kW;Temperature control accuracy:±0.3°C

Chip-Specific High and Low Temperature Test Boxes In the manufacture of semiconductor electronic components for harsh environments, the IC packaging assembly and engineering and production testing phases include electronic thermal testing at temperatures (-85 °C to +200 °C) and other environments. Test the simulation. Once put into practical use, these semiconductor devices and electronic products can be exposed to extreme environmental conditions to meet demanding military and telecommunications reliability standards.

LNEYA represents the international advanced liquid temperature control technology, actively explores and studies component testing systems, mainly used for temperature test simulation in semiconductor testing, with wide temperature orientation and high temperature rise and fall, temperature range -92°C ~ 250°C, suitable for various Test Requirements. LNEYA is committed to solving the problem of temperature control lag in electronic components. Ultra high temperature cooling technology can be cooled directly from 300°C.

| Model | TES-4525 | TES-4555 | TES-45A10 | TES-45A15 | TES-45A25 | |

| TES-4525W | TES-4555W | TES-45A10W | TES-45A25W | TES-45A25W | ||

| Temp. Range | -45℃~250℃ | -45℃~250℃ | -45℃~250℃ | -45℃~250℃ | -45℃~250℃ | |

| Heating Power | 3kW | 5.5kW | 10kW | 15kW | 25kW | |

| Refrigerating output | 250℃ | 3kW | 5.5kW | 10kW | 15kW | 25kW |

| 100℃ | 2.5kW | 5.5kW | 10kW | 15kW | 25kW | |

| 20℃ | 2.5kW | 5.5kW | 10kW | 15kW | 25kW | |

| 0℃ | 2.5kW | 5kW | 10kW | 15kW | 25kW | |

| -20℃ | 1kW | 2.9kW | 6kW | 11kW | 16kW | |

| -40℃ | 0.3kW | 0.9kW | 2kW | 3.8kW | 5.3kW | |

| Temp. control accuracy of heat conduction medium | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| System pressure display | The pressure of the refrigeration system is realized by the pointer type pressure gauge (high-pressure and low-pressure). | |||||

| The circulation system pressure is displayed on the touch screen by pressure sensor detection. | ||||||

| controller | Siemens PLC, Fuzzy PID Control algorithm with Cascade Control algorithm | |||||

| Temp. control | Temperature Control Mode for outlet of Heat conduction medium; | |||||

| External temperature sensor: (PT100 or 4~20mA or communication given) control mode (cascade control) | ||||||

| Programmable5 | procedures can be developed, and each program can be composed of 40 steps | |||||

| Communicating protocol | Ethernet Interface TCP/IP Protocol | |||||

| Internal temp. feedback of equipment | Equipment heat-conducting medium outlet temperature, medium inlet temperature, refrigeration system condensation temperature, ambient temperature, compressor suction temperature, cooling water temperature (configuration of water-cooling equipment) | |||||

| External access temp. feedback | PT100 or 4~20mA or communication given | |||||

| String-level control | The temperature difference between the outlet temperature and the external temperature sensor can be set and controlled; | |||||

| Temp. difference control function | The temperature difference between the inlet temperature and the outlet temperature of the equipment can be set to be controlled (to protect the safety of the system). | |||||

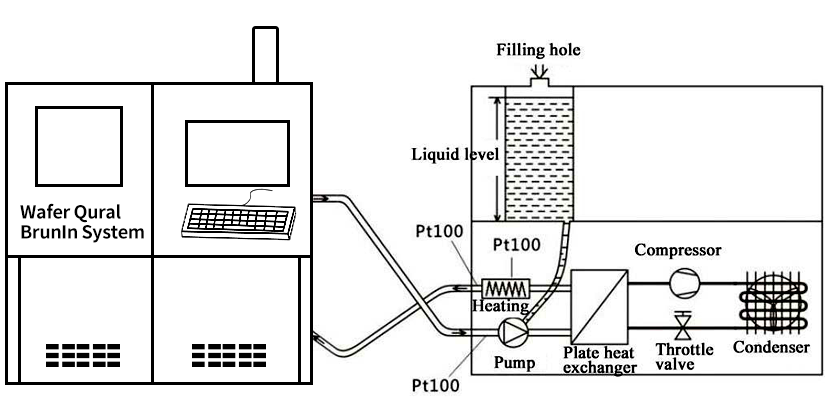

| Closed-cycle system | The whole system is a completely closed system with no oil mist at high temperature and no water in the air at low temperature. The system will not increase the pressure due to high temperature and automatically replenish the heat conduction medium at low temperature. | |||||

| Heating Power | The maximum heating output power of the system (according to each model); | |||||

| The heater has triple protection and independent temperature limiter to ensure the safety of heating system; | ||||||

| The power is more than 10kW and the voltage regulator is adopted, and the heating power output control is controlled by 4-20mA linear control. | ||||||

| Cooling capacity | It refers to the ability to carry away heat at different temperatures (in the ideal state). The actual working conditions need to be considered for environmental heat dissipation. Please enlarge it properly and do well the thermal insulation measures. | |||||

| Circulation pump flow, pressure max | Adopt LNEYA magnetic drive pump | |||||

| 25L/min2.5bar | 50L/min2.5bar | 50L/min2.5bar | 110L/min2.5bar | 150L/min2.5bar | ||

| Compression engine | Tekokang,France | Emerson | Emerson / Danvers | Emerson / Danvers | Emerson / Danvers | |

| Evaporimeter | With DANFOSS/High pressure Plate Heat Exchanger | |||||

| Refrigeration Accessory | Danfoss / Emerson fittings (dry filters, oil separators, high and low pressure protectors, expansion valves) | |||||

| Operation panel | LNEYA custom 7-inch color touch screen, temperature curve display\ EXCEL data export | |||||

| Safe guarding | With self-diagnosis function; phase sequence phase breaker, freezer overload protection; high-voltage pressure switch, overload relay, thermal protection device and other safety protection functions. | |||||

| Cryogen | R-404A / R507C | |||||

| Interface size | ZG1/2 | ZG3/4 | ZG3/4 | ZG1 | DN32 PN10 RF | |

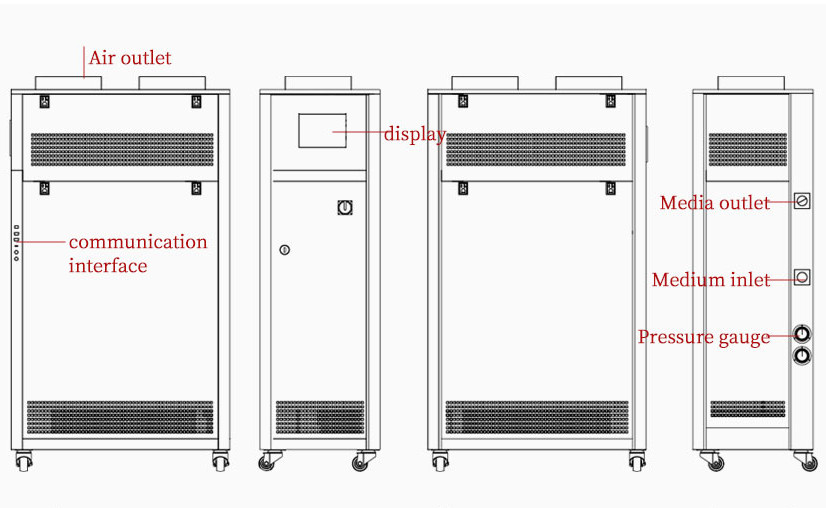

| Shape size (Air-cooled type)cm | 45*70*160 | 55*70*175 | 65*85*185 | 80*120*185 | 100*150*185 | |

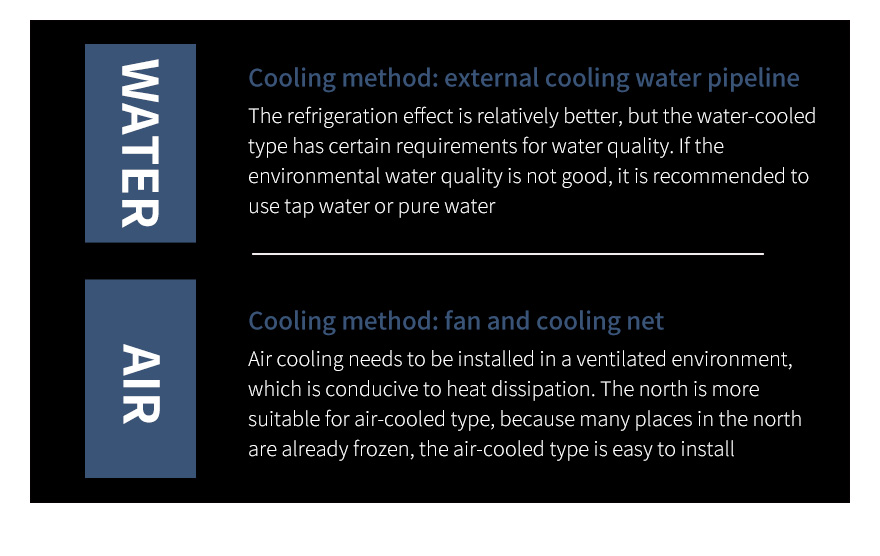

| Air-cooled type | It adopts copper tube aluminum fin condensation method, upper air outlet type, and the condensation fan adopts German EBM axial flow fan. | |||||

| Water-cooled type W | Type W is water cooled | |||||

| Water-cooled Condenser | Casing heat exchanger (Paris / Shen’s) | |||||

| Cooling water quantity at 25℃ | 1.1m3/h | 1.5m3/h | 2.6m3/h | 3.6m3/h | 7m3/h | |

| Source 380V50HZ | 6kW max 220V | 9kW max | 16kW max | 23kW max | 36kW max | |

| Source | Customizable 460V 60HZN 220V 60HZ three-phase | |||||

| Shell material | Cold rolled sheet spray (Standard Colour 7035) | |||||

| Isolation explosion proof | Customizable isolation explosion proof (EXdIIBT4); | |||||

| Installation License No. of Wuxi Guanzi Explosion-proof Product: PCEC-2017-B025 | ||||||

| Barotropic explosion protection | A custom positive pressure explosion-proof (EXPXdmbIICT4) positive pressure system must be a water-cooled device; | |||||

| Installation License No. of Wuxi Guanzi Explosion-proof Product: PCEC-2017-B025 | ||||||

Configuration Details

Working Principle

Suitable for precise temperature control of electronic components. In the manufacture of semiconductor electronic components for harsh environments, the IC packaging assembly and engineering and production testing phases include electronic thermal testing and other environmental testing simulations at temperatures (-45°C to +250°C). Once put into practical use, these semiconductor devices and electronic products can be exposed to extreme environmental conditions to meet demanding military and telecommunications reliability standards.

The model TES -45℃~250℃ products can water-cooled and air-cooled.

RELATED PRODUCTS

Switch more- VIEW

SUNDI -100℃~135℃

Heating Power 3.5kW~80kW Cooling capacity 0.45kW~80kW

- VIEW

SUNDI -90℃~250℃

Heating Power 3kW~80kW Cooling capacity 0.2kW~80kW

- VIEW

SUNDI -80℃~250℃

Heating Power 3kW~80kW Cooling capacity 0.3kW~80kW

- VIEW

SUNDI -70℃~250℃

Cooling capacity 0.4kW~15kW Heating Power 2.5kW~15kW

loading…

No more to see

LNEYA Chillers

LNEYA Chillers