Dynamic Temperature Control Units

PID control algorithm is used to control the temperature of the heat transfer medium inlet pipe at three temperatures of high temperature, normal temperature and low temperature, and the internal circulation pump is connected to the reactor jacket/coil, which can independently control the temperature of the jacket and material. Temperature range -120°C~350°C, fully enclosed pipeline design, single fluid temperature control medium. There are two types: air-cooled and water-cooled.

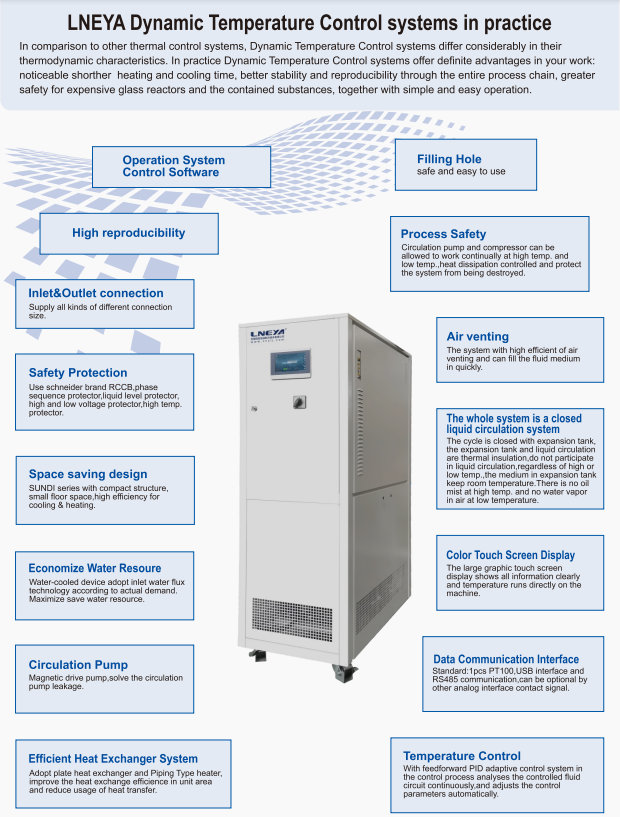

Advantages of SUNDI series temperature control system:

- Cooling power 0.5kW~1200kW

- Heating power 2kW~200kW

- High-precision, intelligent temperature control

- Multifunctional alarm system and safety features

- 7-inch, 10-inch color TFT touch screen graphic display

- With magnetic drive pump, there is no shaft seal leakage problem

- High-temperature cooling technology, which can directly cool down from 300°C

- Efficient production stability and reproducible results

- Fully enclosed system, no need to replace the liquid medium

Typical Application

Dynamic temperature control of high pressure reactor

Dynamic temperature control of double-layer glass reactor

Dynamic temperature control of double-layer reactor

Microchannel Reactor Temperature Control

Distillation system temperature control

Material aging test at low temperature and high temperature

Combinatorial chemical constant temperature control

Semiconductor equipment cooling and heating

Vacuum chamber cooling and heating control

There is no heat transfer medium to evaporate at high temperature, and continuous control of -80~190℃, -70~220℃, -88~170℃, -55~250℃, -30~300℃ can be realized without pressurization temperature;

The fully enclosed pipeline design is adopted to reduce the demand for heat transfer fluid and at the same time improve the heat utilization rate of the system to achieve rapid temperature rise and fall. The heat transfer medium in the expansion vessel does not participate in circulation, which can reduce the risk of heat transfer medium absorbing moisture and volatilization during operation.

LNEYA has a complete process research department, design technology department, engineering implementation department and professional engineering installation department, and a professional engineering service team. The employees have many years of experience in pharmaceutical industry design and construction. Our design and implementation personnel have Participated in the completion of more than 100 pharmaceutical automatic control projects, with sufficient design and implementation experience, can provide users with professional engineering services.

A specially designed lag estimator (model-free self-building tree algorithm) generates a dynamic signal yc(t) instead of the process variable y(t) as a feedback signal. Generate an e(t) signal to the controller, so that the controller does not have a large hysteresis in predicting the control effect, so that the controller can always generate an appropriate control signal. That is to say, this dynamic signal yc(t) can keep the feedback loop working normally even if there is a large lag.

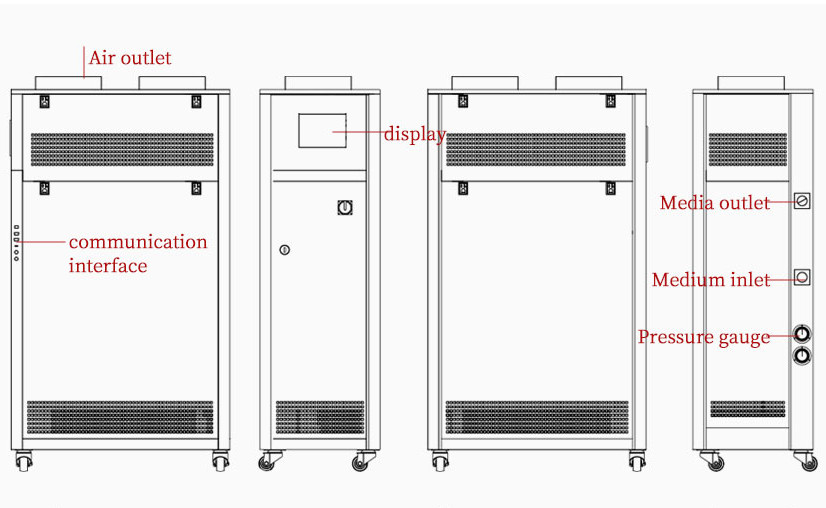

Appearance

Note: please leave your detailed requirements, we will select or customize products for you.

——————————————————————————————————————————————————————————————————————————————————–

Dynamic Temperature Control Systems (Support Customization)

Cooling and Heating Systems (SUNDI series)

Temperature Control Range: -120°C to +350°C

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System, Laboratory, University, Research Institute, Aerospace, Automotive Industry, Semiconductor and Electrical Test, Chemical, Pharmaceutical, Petrochemical, Biochemical, Medical, Hospital, R&D Workshop, Aerospace, Biological and Other Industries.

| Temperature Range | -10 ~ +150°C | -25 ~ +200°C | -45 ~ +250°C | -45 ~ +300°C | -60 ~ +250°C | -70 ~ +250°C | -80 ~ +250°C | -90 ~ +250°C | -100 ~ +100°C | -25 ~+200°C for two reactors | -40 ~+200°C for two reactors |

| Cooling Capacity | up to 15kW | up to 200kW | up to 200kW | up to 25kW | up to 25kW | up to 15kW | up to 80kW | up to 80kW | up to 80kW | up to 10*2kW | up to 10*2kW |

Cooling and Heating Systems (WTD series)

(Micro channel / tube reactors specialized)

Temperature Control Range: -70°C to +300°C

Specialized design for micro channel (small liquid holding capacity, strong heat exchange capacity, circulation system high pressure drop)

| Temperature range | -70°C ~+300°C | -45°C ~+250°C | -70°C ~+200°C |

| Cooling Capacity | up to 7.5kW | up to 5.5kW | up to 50kW |

Cooling and Heating Systems (TES series)

Temperature Control Range: -85°C ~ +250°C

Temp Control Accuracy: ± 0.3°C

| Temperature range | -45°C ~ +250°C | -85°C ~+200°C | -60°C ~+200°C |

| Cooling Capacity | up to 25kW | up to 25kW | up to 60kW |

Cooling and Heating Systems (LTS series)

Temperature Control Range: -80°C to +80°C

It is widely used in the semiconductor process to control the temperature of the reaction chamber, the hot sink plate and the non-flammable heat transfer medium.

| Temperature range | -20°C ~+80°C | -45°C ~+80°C | -60°C ~+80°C | -80°C ~ +80°C |

| Flow Control | 7 ~ 45 L/min | 7 ~ 45 L/min | 7 ~ 45 L/min | 7 ~ 45 L/min |

Cooling and Heating Circulators

Temperature Control Range: -45°C to +250°C

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System, Laboratory, University, Research Institute, Aerospace, Chemical, Pharmaceutical, Petrochemical, Biochemical, Medical, Hospital, R&D Workshop, Aerospace, Biological and Other Industries.

| Temperature range | HR -25°C ~+200°C | HRT -45°C ~+250°C |

| Cooling Capacity | up to 15kW | up to 15kW |

Tell us the temperature control effect you want to achieve, we will customize the corresponding plan for you

LNEYA Chillers

LNEYA Chillers