SUNDI -10℃~150℃ reactor jacket temperature control system

Temperature control of reactor and materialParameters Detailed

● Working temperatures from -120°C to +350°C

● Previously unachievable performance

●Intelligent temperature control

● Maximum process stability and reproducibility

● Adop plate heat exchager, Pipeline heating, the fastest heating and cooling rates.

● High cooling power from 0.5 to 1200kW

● Large temperature range without fluid change

● Closed system, extend thermal fluid lifetime

● 7-inch, 10-inch color TFT touch screen display

● Comprehensive warning and safety functions

● Rapid cooling down from high temperature (from 300 °C)

● Use magnetic drive pump, solve the circulation pump leakage

Configuration Details

Model SUNDI-125SUNDI-125W SUNDI-135SUNDI-135W SUNDI-155SUNDI-155W SUNDI-175SUNDI-175W SUNDI-1A10SUNDI-1A10W SUNDI-1A15SUNDI-1A15W Temp. range -10℃~+150℃ Control Mode Feedback PID + Our special dynamic control calculation, PLC controller Temp. control Process temp. control and jacket temp. control model Temp. difference Set or control the temperature difference between jacket oil and raw material process Program Editor 5 programs, each program can edit 40 steps Communication Portocol MODBUS RTU Protocol, RS485 interface Material temp. feedback PT100 OR 4~20mA or communication(normal: PT100) Temp. feedback The temp. of three points: the inlet and outlet of equipment,reactor material temp.(external temp. sensor) Medium temp. acccuracy ±0.5℃ Material temp. accuracy ±1℃ Heating power kW 2.5 3.5 5.5 7.5 10 15 Cooling capacity kW at 200℃ 2.5 3.5 5.5 7.5 10 15 20℃ 2.5 3.5 5.5 7.5 10 15 -5℃ 1.5 2.1 3.3 4.2 6 9 Circulation pump maxL/min bar 20 35 35 50 50 75 1 1 1 1.2 1.2 1.2 Compressor Mitsubishi Mitsubishi Emerson copeland vortex flexible Emerson copeland vortex flexible Emerson copeland vortex flexible Emerson copeland vortex flexible Expansion valve Electronic expansion valve Evaporator Plate heat exchanger Operation Panel 7-inch touch screen,show temp curve\EXCEL data output Safety protection Self-diagnosis function; freezer overload protection; high pressure switch, overload relay,thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. Closed circulation system The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. Refrigerant R404A/R507C, optional: R448A Connection size ZG1/2 ZG3/4 ZG3/4 ZG1 ZG1 ZG1 Water-cooled type W(cooling water@20℃) 600L/H1.5bar~4bar 800L/H1.5bar~4bar 1000L/H1.5bar~4bar 1200L/H1.5bar~4bar 1600L/H1.5bar~4bar 2000L/H1.5bar~4bar Dimension(water type)mm 400*700*1300 450*700*1600 450*700*1600 550*700*1750 550*700*1750 700*850*1850 Weight kg 115 165 185 235 280 300 Power AC 220V 50HZ 4kW max AC 380V 50HZ 5.6kW max AC 380V 50HZ 8kW max AC 380V 50HZ 10.5kW max AC 380V 50HZ 13.8kW max AC 380V 50HZ 20kW max

| Model | SUNDI-125 SUNDI-125W | SUNDI-135 SUNDI-135W | SUNDI-155 SUNDI-155W | SUNDI-175 SUNDI-175W | SUNDI-1A10 SUNDI-1A10W | SUNDI-1A15 SUNDI-1A15W | |||||||

| Temp. range | -10℃~+150℃ | ||||||||||||

| Control Mode | Feedback PID + Our special dynamic control calculation, PLC controller | ||||||||||||

| Temp. control | Process temp. control and jacket temp. control model | ||||||||||||

| Temp. difference | Set or control the temperature difference between jacket oil and raw material process | ||||||||||||

| Program Editor | 5 programs, each program can edit 40 steps | ||||||||||||

| Communication Portocol | MODBUS RTU Protocol, RS485 interface | ||||||||||||

| Material temp. feedback | PT100 OR 4~20mA or communication(normal: PT100) | ||||||||||||

| Temp. feedback | The temp. of three points: the inlet and outlet of equipment,reactor material temp.(external temp. sensor) | ||||||||||||

| Medium temp. acccuracy | ±0.5℃ | ||||||||||||

| Material temp. accuracy | ±1℃ | ||||||||||||

| Heating power kW | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | |||||||

| Cooling capacity kW at | 200℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | ||||||

| 20℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | |||||||

| -5℃ | 1.5 | 2.1 | 3.3 | 4.2 | 6 | 9 | |||||||

| Circulation pump max L/min bar | 20 | 35 | 35 | 50 | 50 | 75 | |||||||

| 1 | 1 | 1 | 1.2 | 1.2 | 1.2 | ||||||||

| Compressor | Mitsubishi | Mitsubishi | Emerson copeland vortex flexible | Emerson copeland vortex flexible | Emerson copeland vortex flexible | Emerson copeland vortex flexible | |||||||

| Expansion valve | Electronic expansion valve | ||||||||||||

| Evaporator | Plate heat exchanger | ||||||||||||

| Operation Panel | 7-inch touch screen,show temp curve\EXCEL data output | ||||||||||||

| Safety protection | Self-diagnosis function; freezer overload protection; high pressure switch, overload relay,thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. | ||||||||||||

| Closed circulation system | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. | ||||||||||||

| Refrigerant | R404A/R507C, optional: R448A | ||||||||||||

| Connection size | ZG1/2 | ZG3/4 | ZG3/4 | ZG1 | ZG1 | ZG1 | |||||||

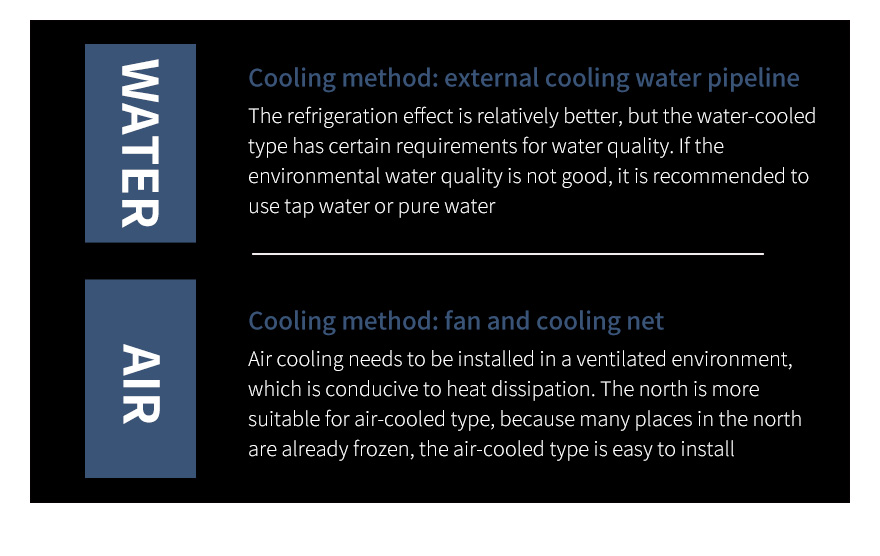

| Water-cooled type W(cooling water@20℃) | 600L/H 1.5bar~4bar | 800L/H 1.5bar~4bar | 1000L/H 1.5bar~4bar | 1200L/H 1.5bar~4bar | 1600L/H 1.5bar~4bar | 2000L/H 1.5bar~4bar | |||||||

| Dimension(water type)mm | 400*700*1300 | 450*700*1600 | 450*700*1600 | 550*700*1750 | 550*700*1750 | 700*850*1850 | |||||||

| Weight kg | 115 | 165 | 185 | 235 | 280 | 300 | |||||||

| Power | AC 220V 50HZ 4kW max | AC 380V 50HZ 5.6kW max | AC 380V 50HZ 8kW max | AC 380V 50HZ 10.5kW max | AC 380V 50HZ 13.8kW max | AC 380V 50HZ 20kW max | |||||||

Working Principle

Ultra-high Temperature Cooling Technology Can Directly Cool Down From 300℃ High Temperature. Because only the heat transfer medium in the expansion chamber is in contact with the oxygen in the air (and the temperature of the expansion tank is between normal temperature and 60℃), which can reduce the heat transfer medium. The risk of oxidizing and absorbing moisture from the air. No high-temperature heat medium evaporates at high temperature, and continuous control can be achieved with -80℃ to 190℃, -70℃ to 220℃, -88℃ to 170℃, -55℃ to 250℃, and -30℃ to 300℃ without pressurization temperature.

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System, Laboratory, University, Research Institute, Aerospace, Automotive Industry, Semiconductor and Electrical Test, Chemical, Pharmaceutical, Petrochemical, Biochemical, Medical, Hospital, R&D Workshop, Aerospace, Biological and Other Industries.

This model is a air-cooled chiller. Use the mixture of ethylene glycol and water for circulating cooling.

LNEYA Chillers

LNEYA Chillers