Parameters Description

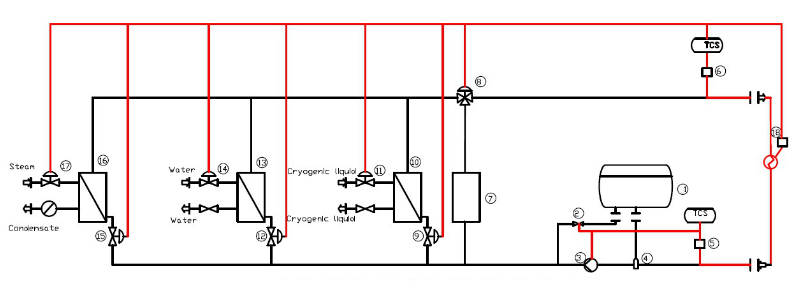

Full closed pipe design is adopted.According to the instructions given by the system PLC, turn on the Angle of the electric control valve and control the flow of the cryogenic liquid into the reactor jacket, thus achieving energy saving and efficiency.All the signals in this process are based on temperature. To ensure the safety operation of the system, electric hair can be fully opened by hand.

TCU temperature control system USES the existing heat (such as steam, cooling water and cryogenic liquid – the “primary”) system infrastructure are integrated into the single fluid system was used to control the temperature of process equipment or in the secondary loop.This achieves only one type of heat transfer liquid can flow into the jacket of the reaction vessel (not directly flow into steam, cooling water or ultra-low temperature liquid).The temperature of the whole reaction process is controlled by operation.

| Model | SR-35N SR-35NS SR-35NH SR-35NSH | SR-50N SR-50NS SR-50NH SR-50NSH | SR-80N SR-80NS SR-80NH SR-80NSH | SR-125N SR-125NS SR-125NH SR-125NSH | SR-200N SR-200NS SR-200NH SR-200NSH |

| Temp. range ℃ | -120~ 250degree setting the max temp according to the supplier heating or cooling source) -40~135degree(The maximum temperature range can be operated by using glycol water formula.) | ||||

| SR-N | A set of cooling heat exchanger, heat exchanger, through proportional adjusting valve control cold heat into the heat exchanger, then through the uniform medium input to the reactor jacketed to do heat exchange and temp. Control, system has inside expansion tank. | ||||

| SR-NS | Besides SR- N function,add one set heater used to reduce high temp. | ||||

| SR-NH | Besides SR- N function,add electrical heating function | ||||

| SR-NSH | Besides SR- N function,add one set heater used to reduce high temp and electrical heating function | ||||

| Expansion tank | 100L | 200L | 280L | 390L | 500L |

| Heat exchanger area | 3.5m2 | 5m2 | 8m2 | 12.5m2 | 20m2 |

| Electric heating function H | 25KW | 35KW | 50KW | 65KW | 80KW |

| With “H” has heating function | |||||

| Control mode | Feed forward PID + Our special dynamic control calculation,LNEYA PLC controller | ||||

| Communication protocol | MODBUS RTU protocol,RS485 interface,optional Ethernet interface/R232 interface | ||||

| Temperature control selection | Material control temp | ||||

| Temperature feedback | The temperature of three points: the inlet and outlet of heat-conducting medium, material in reactor(External temperature sensor), PT100 sensor | ||||

| Material temp. feedback:PT100 or 4~20mA or communication given Temp.feedback:PT100 | |||||

| Process temp. feedback | |||||

| feedback:PT100 | |||||

| Temperature accuracy | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ |

| Circulation pump | 200L/min 2.5BAR | 250L/min 2.5BAR | 400L/min 2.5BAR | 500L/min 2.5BAR | 750L/min 2.5BAR |

| Input and display | 7-inch color touch screen,temperature graph display | ||||

| Safety protection | Self-diagnosis function;freezer overload protection;high pressure switch;overload relay;thermal protection device;liquid low level protection;high temp. Protection and temp. fault protection. | ||||

| Perform valve | Electric proportional control valve, control signal 4~20mA. | ||||

| Piping material | SUS304 | ||||

| Connection size | DN40 | DN40 | DN-50 | DN-65 | DN-80 |

| Dimension mm | 1500*1200*1850 | 1800*1400*2400 | 1500*1500*2050 | 1800*1400*2400 | 2200*1800*2650 |

| Power AC380V50HZ | 2.3kw(max) | 3.5kw(max) | 4.5kw(max) | 8kw(max) | 10.5kw(max) |

| With H power AC380V 50HZ | 27.3kw(max) | 38.5kw(max) | 54.5kw(max) | 73kw(max) | 90.5kw(max) |

| Case material | SUS 304 | SUS 304 | SUS 304 | SUS 304 | SUS304 |

Working Principle

Through three-point sampling (material temperature point, temperature control system outlet temperature, temperature control system inlet temperature), through our company’s own model-free self-built tree algorithm and general anti-lag cascade algorithm.

ZLF Application

Use area: can be used in various explosion-proof areas

The temperature control unit (TCU) is mainly used in reactor heating, cooling temperature control in fine chemical, chemical pharmaceutical, and biopharmaceutical processes. It can realize automatic control of temperature rise, temperature drop, constant temperature and distillation during the reaction process, especially suitable for the reaction process. There is a process control that requires heat and heat.

RELATED PRODUCTS

Switch more- VIEW

SUNDI -100℃~135℃

Heating Power 3.5kW~80kW Cooling capacity 0.45kW~80kW

- VIEW

SUNDI -90℃~250℃

Heating Power 3kW~80kW Cooling capacity 0.2kW~80kW

- VIEW

SUNDI -80℃~250℃

Heating Power 3kW~80kW Cooling capacity 0.3kW~80kW

- VIEW

SUNDI -70℃~250℃

Cooling capacity 0.4kW~15kW Heating Power 2.5kW~15kW

loading…

No more to see

LNEYA Chillers

LNEYA Chillers