LTS -60℃~80℃ Fluoride cooling heating system

Temperature control during semiconductor manufacturingParameters Detailed

1. The pressure holding test of the medium circulation system is 7 bar.

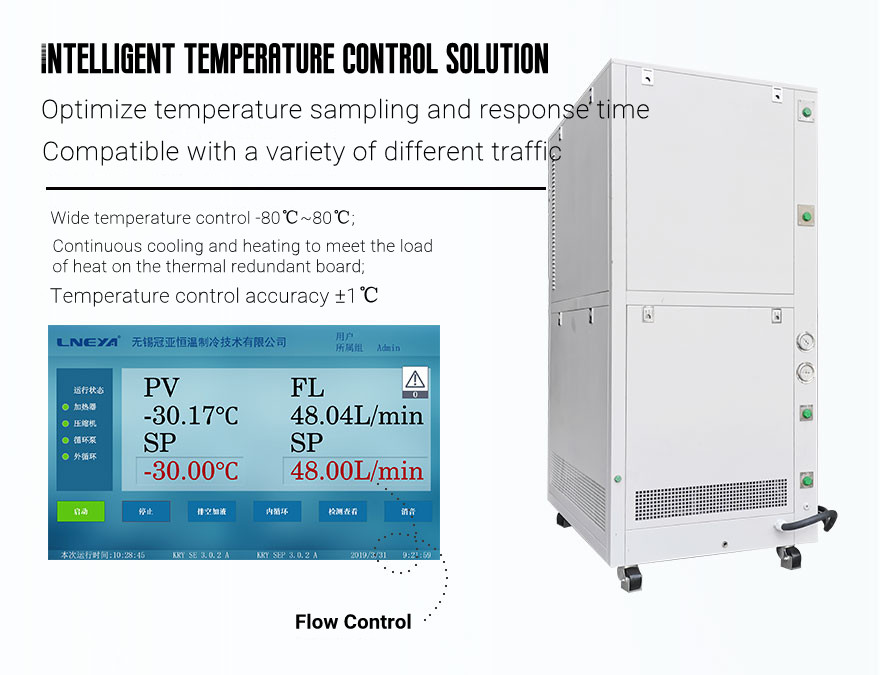

2. Use high-quality magnetic pump without mechanical shaft seal.

3. Optimize temperature sampling and response speed, specially designed control algorithm, can respond quickly to stable temperature control.

4. Enhance the design of circulating pump capacity to meet the high-lift requirements of the system.

5. Continuous high temperature cooling technology meets the requirements of stable operation when heat is loaded on the heat sink plate and requires constant temperature control of cooling and heating.

6. In view of the volatile characteristics of fluorinated liquid, the joint design and system sealing design are strengthened to ensure the service life of the medium.

Electronic fluoride solution is suitable for:

- Semiconductor manufacturing and packaging testing.

- Thermal and cooling media, as well as heat dissipation media for computer servers and electronic component systems.

- Solvent diluents, lubricating diluents, and other solvents for other purposes.

- Thermal Shock (cold and hot shock test fluid).

| Model | LTS-602 | LTS-603 | LTS-604 | LTS-606 | LTS-608 |

| LTS-602W | LTS-603W | LTS-604W | LTS-606W | LTS-608W | |

| Temperature range | -60℃~-20℃ | ||||

| Temperature control accuracy | ±0.1℃ -60℃~-30℃ | ||||

| Flow control | 7~25L/min | 12~45L/min | |||

| The flow control adopts frequency converter adjustment, and the speed is automatically adjusted according to the feedback signal of the flow sensor. The maximum pressure of the circulating pump is 5bar. | |||||

| Internal circulating fluid volume | 4L | 5L | 6L | 8L | 10L |

| Expansion tank volume | 10L | 10L | 15L | 15L | 20L |

| System pressure display | The pressure of the refrigeration system is realized by a pointer pressure gauge (high pressure, low pressure) | ||||

| The pressure acquisition outlet position of the circulatory system is detected by a pressure sensor and displayed on the touch screen | |||||

| Controller | PLC, fuzzy PID control algorithm, with cascade control algorithm | ||||

| Temperature control | Heat transfer medium outlet temperature control mode | ||||

| External temperature sensor: (PT100 or 4~20mA or communication setting) control mode (cascade control) | |||||

| Letter of agreement | Ethernet interface TCP/IP protocol | ||||

| RS485 interface modbus RTU protocol | |||||

| Internal temperature feedback of equipment | Equipment heat transfer medium outlet temperature, medium inlet temperature, refrigeration system condensation temperature, ambient temperature, compressor suction temperature, cooling water temperature (available for water-cooled equipment) | ||||

| Closed circulation system | The whole system is a fully enclosed system, low temperature does not absorb moisture in the air, does not volatilize the heat transfer medium, and the low temperature automatically supplements the heat transfer medium into the circulation system | ||||

| Compressor | Emerson Copeland/Danfoss Scroll Flexible Compressor | ||||

| Circulating pump | Magnetic circulation pump | ||||

| Evaporator | Plate heat exchanger | ||||

| Condenser | Micro channel condenser (air-cooled) | ||||

| Plate heat exchanger (water-cooled), special attention: clean factory water is required | |||||

| Refrigeration accessories | Danfoss/Emerson accessories (filter drier, oil separator, high and low pressure protector, expansion valve) | ||||

| Operation panel | Wuxi Guanya customized 7-inch color touch screen, temperature curve display\EXCEL data export | ||||

| Security | With self-diagnosis function; phase sequence open-phase protector, refrigerating machine overload protection; high-pressure pressure switch, overload relay, thermal protection device and other security functions. | ||||

| In and out interface size | ZG1/2 | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 |

Configuration Details

This model can be air-cooled or water-cooled.

RELATED PRODUCTS

Switch more- VIEW

LTS -40℃~35℃

Flow control 12L/min~45L/min Medium: Fluoride

- VIEW

LTS -20℃~80℃

Flow control 12L/min~45L/min Medium: Fluoride

loading…

No more to see

LNEYA Chillers

LNEYA Chillers