KRY -40℃~100℃ Battery Test Cooling Chiller

Vehicle antifreeze test temperature simulationParameters Detailed

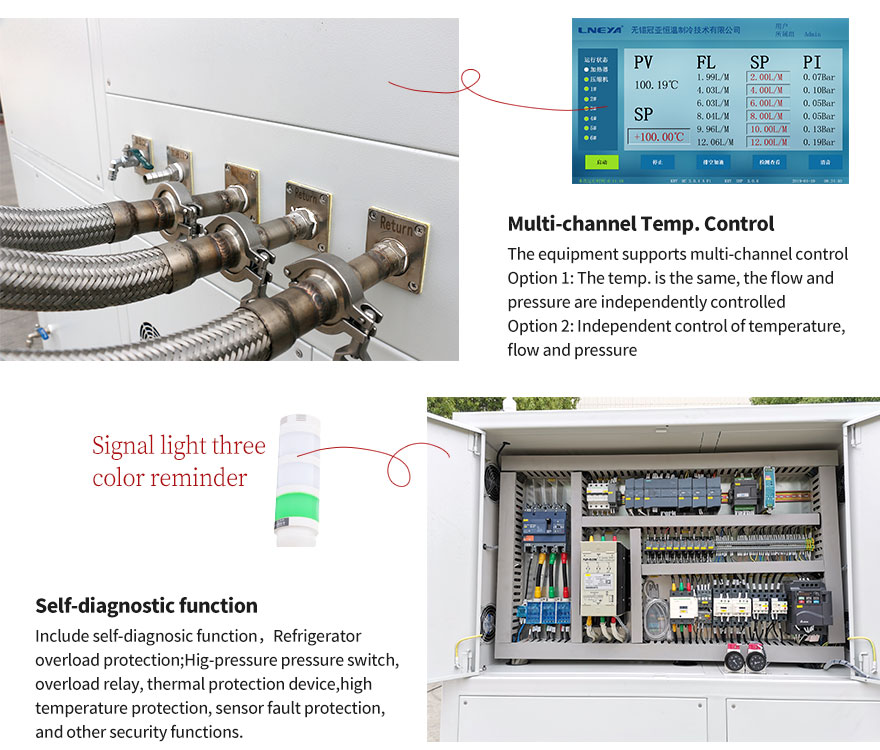

Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. The equipment can control the flow and pressure independently while controlling the temperature, and different customized solutions are required for simultaneous control.

The tested object is attached to a test platform adapter.

The inside of the part was cooled and heated by an aqueous solution of ethylene glycol.

The test component needs to go through a specific temperature profile and record changes in temperature.

Temperature variations typically range from -40 ℃to 100 ℃. (expandable to 150 ℃)

When performing a tolerance test, it usually takes an infinite loop.

Equipped with a powerful circulation pump while ensuring the delivery of highly viscous liquids.

Control the flow output with variable frequency regulation or proportional control valve to achieve high precision control total range 5%~100% adjustment.

KRY -40℃~100℃

| Model | Synbol Unit | KRY-455/455W | KRY-475 | KRY-4A10/4A10W | KRY-4A15/4A15W | KRY-4A25/4A25W | KRY-4A38W | KRY-4A60W |

| Temp Range | ℃ | -40℃~+100℃ | ||||||

| Flow rate output | L/min | 1~10 L/min | 1~25 L/min | 1~25 L/min | 1~40 L/min | 1~40 L/min | 5~50 L/min | 5~50L/min |

| Flow rate accuracy | L/min | ±0.2 L/min | ||||||

| Heating power | kW | 5.5kW | 7.5kW | 10kW | 10kW/Optional 15kW | 15kW/Optional 25kW | 25kW/Optional 38kW | 38kW/Optional 60kW |

| Cooling Capacity | 100℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW |

| 200℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| 0℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| -35℃ | 1.2kW | 1.8kW | 2.5kW | 4kW | 6.5kW | 10kW | 15kW | |

| Refrigerant | R404A/ R507C | |||||||

| Power 380V50HZ | kW max | 12kW max | 15kW max | 20kW max | 29kW max | 42kW max | 58kW max | 84kW max |

| Dimension(W) cm | (W) cm | 55*95*175 | 55*95*175 | 55*95*175 | 70*100*175 | 80*120*185 | 100*150*185 | 145*205*205 |

| Dimension(A) cm | (A) cm | 55*95*175 | 55*95*175 | 70*100*175 | 80*120*185 | 100*150*185 | ||

| Weight (water cooling) | KG | 250KG | 280KG | 320KG | 360KG | 620KG | 890KG | 1300KG |

KRY -40℃~100℃ 1&2s Temperature/Pressure/Flow can be independently controlled

| Model | Synbol Unit | KRY-475/475W/2S | KRY-4A15W/2S | KRY-4A25W/2S | KRY-4A38W/2S | KRY-4A60W/2S |

| Temp Range | ℃ | -40℃~+100℃ | ||||

| Flow rate output | L/min | 1~20 L/min | 1~20 L/min | 1~20 L/min | 1~40 L/min | 1~40 L/min |

| Flow rate accuracy | L/min | ±0.2 L/min | ||||

| Heating power | kW | 7.5kW | 10kW | 15kW | 25kW | 38kW |

| Cooling Capacity | 100℃ | 10kW | 15kW | 25kW | 38kW | 60kW |

| 200℃ | 10kW | 15kW | 25kW | 38kW | 60kW | |

| 0℃ | 10kW | 15kW | 25kW | 38kW | 60kW | |

| -35℃ | 2.5kW | 4kW | 6.5kW | 10kW | 15kW | |

| Refrigerant | R404A/R507C/R125/N40 | |||||

| Power 380V50HZ | kW max | 16.5kW | 24kW max | 36kW max | 56kW max | 81kW max |

| Dimension(A) cm | (A) cm | 70*100*175 | 80*120*185 | 100*150*185 | 120*180*205 | 145*205*225 |

| Weight (water cooling) | KG | 360KG | 450KG | 750KG | 1000KG | 1700KG |

KRY -40℃~100℃ 1&2T (2 sets of auxiliary temperature control, Pressure/Flow controlled separately)

| Model | Synbol Unit | KRY-475/475W/2T | KRY-4A15W/2T | KRY-4A25W/2T | KRY-4A38W/2T | KRY-4A60W/2T |

| Temp Range | ℃ | -40℃~+100℃ | ||||

| Flow rate output | L/min | 1~20 | 1~20 | 1~20 | 1~40 | 1~40 |

| Flow rate accuracy | L/min | ±0.2 L/min | ||||

| Heating power | kW | 7.5kW*2 | 10kW*2 | 15kW*2 | 25kW*2 | 38kW*2 |

| Cooling Capacity | 100℃ | 10kW*2 | 15kW*2 | 25kW*2 | 38kW*2 | 60kW*2 |

| 200℃ | 10kW*2 | 15kW*2 | 25kW*2 | 38kW*2 | 60kW*2 | |

| 0℃ | 10kW*2 | 15kW*2 | 25kW*2 | 38kW*2 | 60kW*2 | |

| -35℃ | 2.5kW*2 | 4kW*2 | 6.5kW*2 | 10kW*2 | 15kW*2 | |

| Refrigerant | R404A/R507C/R125/N40 | |||||

| Power 380V50HZ | kW max | 30kW | 45kW max | 70kW max | 108kW max | 158kW max |

| Dimension(A) cm | (A) cm | 70*100*175 | 80*120*185 | 100*150*185 | 120*180*205 | 145*205*225 |

| Weight (water cooling) | KG | 660KG | 850KG | 1350KG | 1800KG | 2600KG |

KRY -40℃~100℃ 1&3S (3 sets of auxiliary temperature control, Pressure/Flow controlled separately)

| Model | Synbol Unit | KRY-4A15W/3S | KRY-4A25W/3S | KRY-4A38W/3S | KRY-4A60W/3S | KRY-4A25W/6S | KRY-4A38W/6S | KRY-4A60W/6S |

| Temp Range | ℃ | -40℃~+100℃ | ||||||

| Flow rate output | L/min | 1~20 | 1~20 | 1~20 | 1~40 | 1~20 | 1~20 | 1~40 |

| Flow rate accuracy | L/min | ±0.2 L/min | ||||||

| Heating power | kW | 10kW | 15kW | 25kW | 38kW | 15kW | 25kW | 38kW |

| Cooling Capacity | 100℃ | 15kW | 25kW | 38kW | 60kW | 25kW | 38kW | 60kW |

| 200℃ | 15kW | 25kW | 38kW | 60kW | 25kW | 38kW | 60kW | |

| 0℃ | 15kW | 25kW | 38kW | 60kW | 25kW | 38kW | 60kW | |

| -35℃ | 4kW | 6.5kW | 10kW | 15kW | 5kW | 8kW | 13kW | |

| Refrigerant | R404A/R507C/R125/N40 | |||||||

| Power 380V50HZ | kW max | 23.5kW max | 36kW max | 55kW max | 82kW max | 38kW max | 55kW max | 82kW max |

| Dimension(A) cm | (A) cm | 80*120*185 | 100*150*185 | 120*180*205 | 145*205*225 | 120*180*205 | 145*205*225 | 145*205*225 |

| Weight (water cooling) | KG | 420KG | 750KG | 1000KG | 1700KG | 900KG | 1200KG | 1950KG |

KRY -40℃~100℃ 1&6S (6 sets of auxiliary temperature control, Pressure/Flow controlled separately)

| Model | Synbol Unit | KRY-4A25W/6S | KRY-4A38W/6S | KRY-4A60W/6S |

| Temp Range | ℃ | -40℃~+100℃ | ||

| Flow rate output | L/min | 1~20 | 1~20 | 1~40 |

| Flow rate accuracy | L/min | ±0.2 | ||

| Heating power | kW | 15 | 25 | 38 |

| Cooling Capacity | 100℃ | 25kW | 38kW | 60kW |

| 200℃ | 25kW | 38kW | 60kW | |

| 0℃ | 25kW | 38kW | 60kW | |

| -35℃ | 5kW | 8kW | 13kW | |

| Refrigerant | R404A/R507C/R125/N40 | |||

| Power 380V50HZ | kW max | 38 | 55 | 82 |

| Dimension(W) cm | ||||

| Dimension | (A) cm | 120*180*205 | 145*205*225 | 145*205*225 |

| Weight (water cooling) | KG | 900 | 1200 | 1950 |

KRY sreies Configuration Details

| Control Mode | Feedback PID + Our special dynamic control calculation, PLC controller | ||||||||

| Temp. control | Process temp. control and jacket temp. control model | ||||||||

| Temp. difference | Set or control the temperature difference between jacket oil and raw material process | ||||||||

| Program Editor | 10 programs, each program can edit 40 steps | ||||||||

| Communication Portocol | MODBUS RTU Protocol, RS485 interface | ||||||||

| Material temp. feedback | PT100 OR 4~20mA or communication(normal: PT100) | ||||||||

| Temp. feedback | The temp. of three points: the inlet and outlet of equipment,reactor material temp.(external temp. sensor) | ||||||||

| Expansion valve | Emerson thermal expansion valve/danfoss thermal expansion valve | ||||||||

| Evaporator | DANFOSS/KAORI Plate heat exchanger | ||||||||

| Operation Panel | 7-inch touch screen,show temp curve\EXCEL data output | ||||||||

| Safety protection | Self-diagnosis function; freezer overload protection; high pressure switch, overload relay,thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. | ||||||||

| Closed circulation system | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. | ||||||||

| Refrigerant | R404A/R507C/R125/N40 All four refrigerants are available | ||||||||

Working Principle

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Test temperature of main test items of vehicle electronics:

IC test conditions for locomotives: -40℃~125℃, wind blowing, sun exposure, high vibration;

Instrument panel operation test test conditions: -40℃~85℃;

Motor controller test conditions: operating test temperature: 40 ℃ ~ 110 ℃;

Satellite positioning (GPS) Test conditions: high temperature operation test temperature: 85℃; low temperature operation test temperature: -40℃;

Compound vibration: -40℃~80℃;

Obviously the best solution is for the test house to have temperature simulation system equipment.

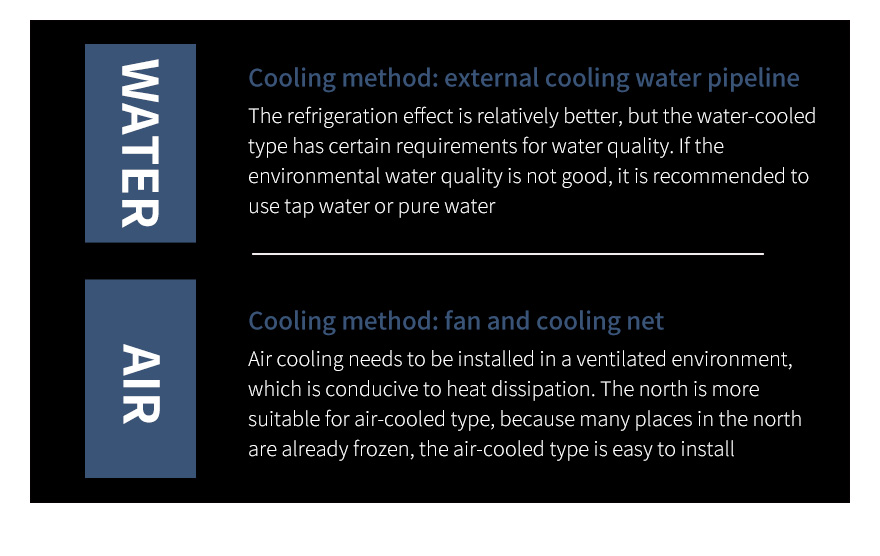

The model KRY -40℃~100℃ products can water-cooled and air-cooled.

RELATED PRODUCTS

Switch more- VIEW

KRY -20℃~100℃

Heating Power 15kW~38kW Cooling capacity 10kW~60kW

- VIEW

KRY -25℃~100℃

Heating Power 5.5kW~25kW Cooling capacity 2.8kW~38kW

- VIEW

KRY 0℃~100℃

Heating Power 2.5kW~38kW Cooling capacity 2.5kW~60kW

loading…

No more to see

LNEYA Chillers

LNEYA Chillers