Parameters Detailed

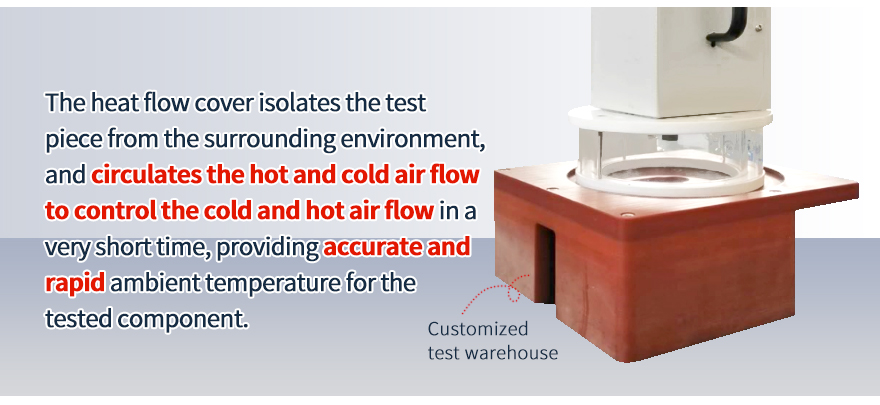

Provides accurate and fast ambient temperature (-120 °C ~ +300 °C) for chips, modules, integrated circuit boards, and electronic components. It is an indispensable instrument for product electrical performance testing, failure analysis, and reliability assessment.

Widely used in semiconductor companies, aerospace, optical communications, universities, research institutes and other fields.

Compared to the traditional thermostat, there are several features:

Temperature range: -120 °C ~ +300 °C;

The temperature rise and fall is very fast, -55 °C ~ 150 °C < 10 seconds;

Temperature control accuracy: ±1 °C;

Temperature setting capability: ±0.1 °C;

Temperature display capability: ±0.1 °C;

Maximum air flow: 25m3/h;

Real-time monitoring of the real temperature of the IC under test to achieve closed-loop feedback and adjust the gas temperature in real time;

The temperature rise and fall time is controllable, programmable operation, manual operation and remote control.

| Model | @ Temperature ℃ | AES-4535 | AES-6035 | AES-8035 | AES-A1035W | AES-A1235W |

| Model | AES-4535W | AES-6035W | AES-8035W | |||

| Temp. Range | -45℃~225℃ | -60℃~225℃ | -80℃~225℃ | -100℃~225℃ | -120℃~225℃ | |

| Temp. Control Accuracy | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ | |

| Temp. Conversion Time | -25℃ to 150℃ Approximately 10S 150℃ to -25℃ Approximately 20s | -45℃ to 150℃ Approximately 10S 150℃to -45℃ Approximately 20s | -55℃ to 150℃ Approximately 10S 150℃to -55℃ Approximately 15s | -70℃ to 150℃ Approximately 10S 150 ℃to -70℃ Approximately 20s | -80℃ to 150℃ Approximately 11S 150℃to -80℃ Approximately 20s | |

| Compression Engine | Taikang,France | Taikang,France | Taikang,France | Italy Duling | Italy Duling | |

| Shape Dimension (Wind)cm | 54*69*132 | 54*59*132 | 75*73*133 | 80*120*185 | 100*150*185 | |

| Shape Size (Water)cm | 54*69*132 | 54*69*132 | 75*73*133 | 70*100*175 | 80*120*185 | |

| Cooling Water Quantity At 25℃ | 0.6m3/h | 1.2m3/h | 1.6m3/h | 2.6m3/h | 3m3/h | |

| Source 380V 50HZ | 3.7kW max | 5kW max | 5kW max | 6.8kW max | 7.5kW max |

| Air Requirement | Air Cleaner<5um |

| Air Oil Content:<0.1ppm | |

| Air Temp&Humidity:5℃~32℃ 0~50%RH | |

| Air Handing Capacity | 7m3/h ~ 25m3/h Pressure 5bar~7.6bar |

| System Pressure Dispiay | Pressure of Refrigeration system is realized by pressure gauge (High pressure, low pressure); |

| Pressure of circulatory system is detected by pressure sensor and displayed on touch screen. | |

| Controller | PLC, Fuzzy PID Control algorithm. |

| Temp. Control | Control of outlet temperature |

| Programmable | 10 procedures can be developed, and each program can be composed of 45 steps |

| Communicating Protocol | Ethernet Interface TCP/IP Protocol. |

| Internal Temp. Feedback | Equipment outlet temperature, refrigeration system condensation temperature, ambient temperature, compressor suction temperature, cooling water temperature (water cooling equipment is configured) . |

| Temp. Feedback | T Temperature Sensor |

| Evaporimeter | Double-pipe (heat) Exchanger |

| Calorifier | Flanged Barrel Heater |

| Refrigeration Accessory | Danfoss / Emerson fittings (dry filters, oil separators, high and low pressure protectors, expansion valves, solenoid valves). |

| Operation Panel | LNEYA custom 7-inch color touch screen, temperature curve display\ EXCEL data export. |

| Safe Guarding | With self-diagnosis function; phase sequence phase breaker, freezer overload protection; high-voltage pressure switch, overload relay, thermal protection device and other safety protection functions. |

| Cryogen | Topsubmixed Refrigerant |

| External Insulation Hose | 8m DN32 fast coupling clamp for easy outgoing insulation hose |

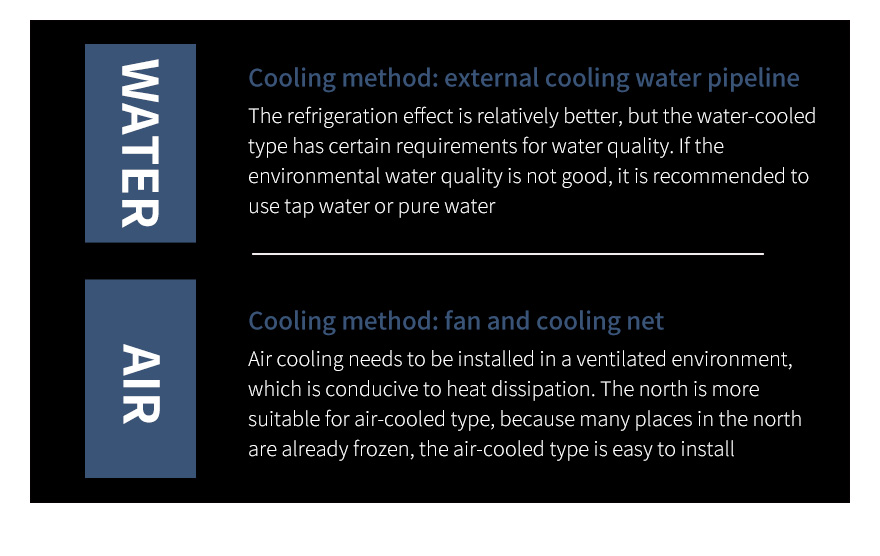

| Air-Cooled Type | Copper tube aluminum fin condensation mode, upper and out type, condensing fan using Germany EBM axial flow fan. |

| Water-Cooled Type W | Type W is water cooled |

| Water-Cooled Condenser | Sleeve type heat exchanger (Paris/ Shen’s) |

| Source | Customizable 460V 60HZN 220V 60HZ three-phase |

| Shell Material | Cold rolled sheet spray (Standard Colour 7035). |

| Temp. Spread | High Temperature To +300℃ |

Temperature Forcing System Applications

Suitable for precise temperature control of electronic components. In the manufacture of semiconductor electronic components for harsh environments, the IC packaging assembly and engineering and production testing phases include electronic thermal testing and other environmental testing simulations at temperatures (-45°C to +250°C). Once put into practical use, these semiconductor devices and electronic products can be exposed to extreme environmental conditions to meet demanding military and telecommunications reliability standards.

The model AES -115℃~225℃ products can gas cooling chiller & water cooled chiller.

RELATED PRODUCTS

Switch more- VIEW

LTS -60℃~80℃

Flow control 12L/min~45L/min Medium: Fluoride

- VIEW

LTS -40℃~35℃

Flow control 12L/min~45L/min Medium: Fluoride

- VIEW

LTS -20℃~80℃

Flow control 12L/min~45L/min Medium: Fluoride

- VIEW

TES -60℃~200℃

Heating Power 15kW~60kW Cooling capacity 3kW~60kW

loading…

No more to see

LNEYA Chillers

LNEYA Chillers